|

Pack Rat Work Shop |

|

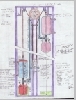

Hot Water Powered Cable Drum Engines These systems are very simple in operation. Basically a tank full of propane or freon gas is lowered into a tank of hot water. The gas then expands and moves into a tank above that is filled with water. This causes the water to be pumped through a hose and then into another tank. When the second tank is full, it is released to drop pulling the cables and the original tank is lifted to the top of the machine in preperation for the cycle to start again. Cables hooked to the tanks cause a 3.8″ drum to turn one revolution per one foot of cable. This drum drives the main output shaft though a bike chain arrangement. The output can be setup or cycle back and forth or turn in one direction only. |

|||||||||||

|

|

Hot Water Powered Cable Drum Engines

This is a system that uses #20 lb propane tanks at the gas tanks and #40 lb propane tanks as the water tanks. About .2 hp when cycling.

This version system uses 12 gallon air tanks for the gas and 30 gallon air tanks for the water and will put out close to 1/2 hp when cycling. This setup uses only 12 gallon air tanks and also puts out about .2 hp when cycling. This version also has the mechanical release system versus a magnet as in version 1.2 . A closeup of the mechanical release system.

Diagram of a water type solar panel I plan to use with one of these systems. This version uses 30 and 12 gallon air tanks and will output about .47 hp when cycling. This setup also uses the mechanical release system. This version is like the one above but this system will output power almost continuously. During the pumping part of the cycle the hydraulic motor will output approximately .2 hp to the main output shaft and during the tank drop part of the cycle the tank cable drum will output approximately .47 hp to the main output shaft. It will only stop output for a few seconds at the end of each cycle. Real world output should be about 8 amps 12v during pumping and about 20 amps 12v during the drop. This is the add-on section that allows power output during the pumping part of the cycle. This one according to the math (If I haven’t messed it up) is capable of a max of about 50 amps at 12.6 volts for charging if a 200 psi differential pressure is used. That should be about 130-140 degree’s f in the hot water tanks… It should have about a 3 run minute cycle and then 10-30 seconds to drop and start heating the next tank. It will also pump it’s own water for the tanks at two gallons a cycle. The pumps will keep the full tanks from just slamming down when released. This is another version of the one above. Instead of electricity it has a mechanical output of about 1 hp with a maximum of 640 rpm. |

||||||||||