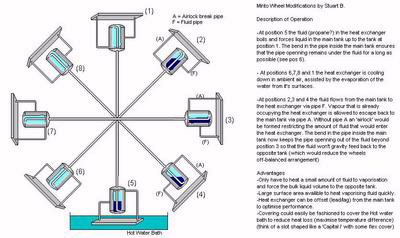

The Wallace Minto wheel is a very simple device. It works simply by using the pressure generated by a liquid that has a very low boiling point. The liquid is pumped from the lower tank to the upper one and gravity does the rest. The simplest method of heating the liquid is by submersing the lowest tank and a tank of hot water. This can be supplied by solar panel extremely easily.

The basic minto wheel operates at a very slow speed. This is normally less than 5 rpm and normally only 1 or 2 rpm. What the wheel can supply is alot of torque at that slow speed and so it can be geared up to a higher speed.

The basic wheel as generaly built has some limitiations though due simply to the way it is constructed. Most designs tend to heat the entire lower tank of fluid and then try to pump it through a fairly small pipe to the opposite tank. In the pics along the bottom of the page you can see one of the original wheels and a “Mother Earth’s News” version they built to try out the idea. (click any of the pics for larger views)