|

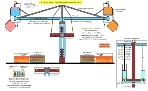

Big wind up generator system powered by hot water from solar panel

This is a very simple system that uses hot water from a solar panel to operate one of my NITI driven or Minto type teeter-totter setups. The teeter-totter can be equiped with a ratchet type mechanism that would turn a gear and chain driving another gear connected through a clutch to a cable winding reel mounted on an axle with one-way bearings.

The reel winds up a cable with a large weight on the end of it. As the weight reaches a certain height the clutch releases the reel from the gear allowing the cable to unwind. This turns the axle through one-way bearings and causes it to spin a large flywheel mounted on the same axle. On the other side of the flywheel is a generator/alternator that is used to charge batteries.

The weight will run out of cable just as it hits the ground (padded) This will stop the reel from spinning and should allow the clutch to reset and start to rewind the cable again for the next cycle.

If the flywheel is matched up with enough weight and the right size gen/alt, it should keep spinning for a few minutes each time the cable drops providing a charge for the batteries.

More than one reel can be installed on each axle to spin the flywheel more often. I was considering 6 on an 8 foot axle. One solar panel could provide 140 degree F hot water for quite a number of the teeter-totters as they only require a very small amount of water to immerse the NITI springs in during operation. At only 1 ft wide per teeter totter a six cable setup wouldn’t take up too much space at least in one direction. The other direction would depend entirely on how much weight it is trying to lift. The more weight, the longer the arms of the teeter totter would have to be to get enough leverage. Alternatively a larger ratchet wheel could be used but that would slow rewinding also. The size of the whole system would be based on the size of the weight and flywheel and would have to be balanced for the longest usefull spin speed of the gen/alt possible with the shortest rewind time.

The first clutch mechanism is operated by 2 solenoids that are fitted inside a round frame. Two bars come out the side catch the teeth on the reel. Two power bands are on the left beside the chain gear that supply power for the solenoids

The second drawing (grey one) shows the full setup from the end using simple levers to operate the release and winding of the cable reel. This version is simple enough anyone could build it without a machine shop. Most of the parts could be sand casted.

When the clutch ball moves the long pivot arm , the arm forces the cranking pole away from the reel and as it reaches the end of it’s travel, it also releases the ratchet on the reel so it can unwind. While the weight is dropping two magnets lock the operating arms together and the ratchet out of the way. As the cable reaches the end another ball mounted at the end of the reel end of the cable forces between two wedges in front of the magnets on the arms forcing them apart and the levers to reset their positions for winding up the cable again. A weight or spring can be used to move the levers back to position.

The next 2 pics are the basic teeter- totter setups. The first one is the NITI setup and the next tis a modified minto type setups for faster operation.

The tanks are not shown in the second pic but they would be just like all the rest of the pics.

More information on the teeter totter capabilities and how it works (including a complete wheel drawing ) is available on my Minto Wheel page.

|