|

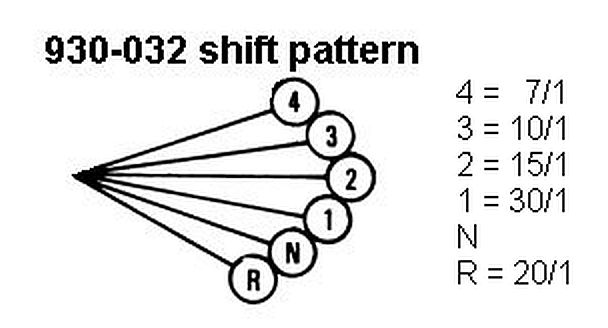

Last year my leg finally got to the point I was having trouble riding my recumbent trike more than a couple of miles so I decided it was times to build me something new that would still be legal for road use but that I didn’t have to pedal. After looking around a bit at what was available I decided I liked the style of a Palmer Mobility trike. http://palmerind.com/electric/independ.php The following pictures below show what I ended up with. There are still have a couple minor changes I want to make such as changing the drive chains and sprockets I used over to pulleys and tooth type belts to make it quieter and I want to use a solar panel that can charge the batteries instead of the regular canopy top like they use. I’m slowly making changes but like everything else I have to save up money before I can do it and so it’s getting done much slower than I prefer but I can still use it while waiting. The batteries are two 12 volt 110 amphour lead acid marine batteries that give about 30 miles range before needing to be charged again. I have a 110volt a.c. marine charger built into the rear end below the motors that handles charging and equalizing the batteries. That charger will be used as a backup once I get the solar panel bought and installed. The top speed in 4th gear on level ground is 15 mph. I did that on purpose because here in NC the speed limit for motor assist power on an electric bike or trike is 20 mph. Even though this is just a big mobility scooter which falls under different state laws I didn’t see any point in getting into any arguments with the police over it. Besides, that is 2x faster than my little small mobility scooter. It doesn’t really need to go any faster in my opinion. Normally I only use 3rd and 4th gear most of the time because the other two are simply too slow for any real purpose other than climbing a hill or maybe using the trike for plowing my wife’s garden. It will climb a 45 degree angle in 2nd gear though as long as the rear wheels can get traction. I really haven’t needed 1st for anything yet. The trike has a full led lighting system consisting of dual headlights, running lights, turn signals and brake lights. It even has a switch to use the turn signals as emergency blinkers like on a car. It also has orange and red reflector tape all over it. It’s pretty hard to miss in the dark when lights are shining on it. That was pretty much the idea when I painted the frame fluorescent orange. It’s pretty visible in the daytime too. Scooter band brakes were on used on both the front and the rear wheels. The left rear is hooked up to a lever in front of the wheel on the frame to act as a parking brake. The transmission disk brake is also hooked up to a foot pedal bar as seen in the pictures below. UPDATE – The scooter is now using a drum brake on the front wheel and the transmission brake for the rear wheels. The wheels on the scooter have been replaces with moded aluminum mag wheels and there wasn’t room to use a brake on the right rear wheel. Originally all the tires were the same size 20″-2.25″ diameter and all used the no-flat foam rubber tubes but I found that the trike was just a bit too heavy for them in the rear and they tended to get flat spots if it sat in the same spot for more than a couple of days. They would round back out without a problem after about a block of riding but it was bump-bump-bump until they finally did. The seat I used is designed for a small MasseyFerguson tractor. It’s very comfortable! UPDATE- While the seat has been very comfortable to use it should not have been advertized as weather proof. The covering started cracking and small splits appeared after about 3 months use. So far I’ve been able to repair it with one of those seat repair kits but I think I’m going to have to get some sort of real weatherproof cover for it. The rear fold down frame is actually a steel rear cargo carrier I got from Harbor Freight Tools that normally mounts on the trailer hitch of a truck or car. I only used half of it and hinged it to the top of the rear frame. It has two arms that drop down and are pinned to the bottom frame for support when I let it down. The basket behind the seat is made from some commercial refrigerator shelving I recycled from a local dumpster.

I’ve been pretty satisfied with it. The only problem I have is everytime I go somewhere shopping with it, multiple people keep stopping me to ask where I got it from. This is the only one like it around here as far as I know. I’ve never seen anyone on a Palmer version so most of the people in this town have never seen anything like it.

Picture showing the new moped mag wheels and sun top I made for it.

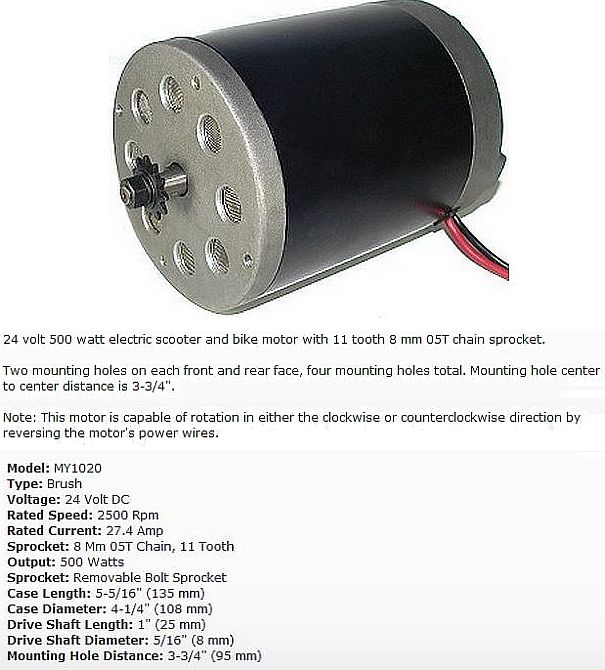

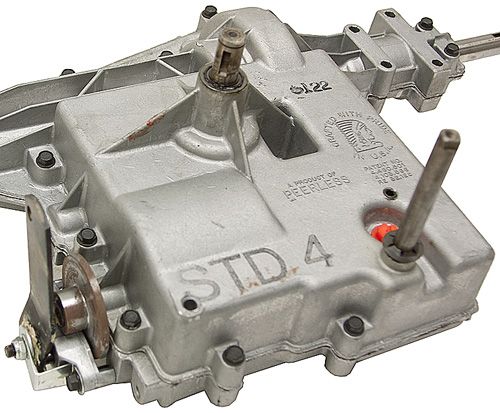

Here is the one of the two identical motors and transmission I used. The listing on the motor is slightly incorrect. The max rpm is 3000 and not 2500 rpm according to the motor name plates what were on them when I got them.

I had to figure out the gear ratios on the transmission by hand by turning the input and counting the output and these are the numbers I came up with.

The main frame of the trike was built using 2″ car exhaust pipe and recycled bed rail angle iron.

I even had a friend of mine make me a custom built by metal tag for it that is mounted on the right side of the seat under the main power switch

If you would like to see all the build pictures not shown here (most of them) you can dload the zipped file here. Clonepics it’s about a 13 megabyte file |